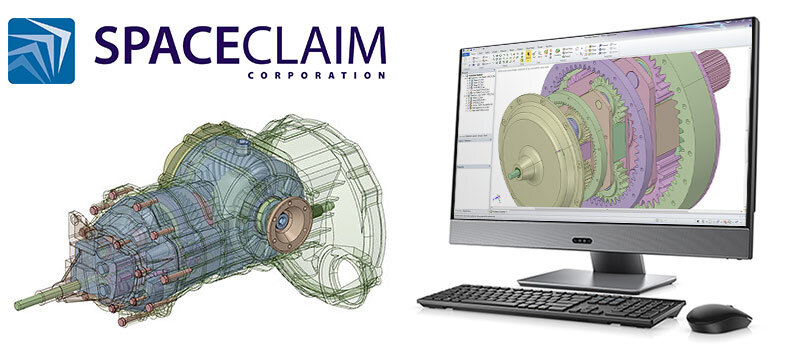

ANSYS Discovery SpaceClaim

Multipurpose 3D Modeling for Faster Engineering Results

ANSYS Discovery SpaceClaim is a multipurpose 3D modeling application providing efficient solutions to common modeling tasks. Built on the direct modeling technology, Discovery SpaceClaim removes geometry problems associated with various 3D CAD operations, such as design or concept modeling, repair of translated CAD files, general model defeaturing, and complete model editing. With its premise of ease of use and simplicity, you’ll find Discovery SpaceClaim to be extremely valuable in tackling small to large modeling problems.

A New Way of 3D Modeling

Discovery SpaceClaim’s unique user interface, modeling technology and versatile toolset enable you to easily create and modify geometry without the complexity associated with traditional CAD systems. When working with existing CAD models, you can defeature and simplify geometry with automated, easy-to-learn tools. Discovery SpaceClaim is ideal for engineers who don’t have time for heavy CAD tools but want and need to get fast answers using 3D.

Ease of Use

We believe that technology should work for you, not the other way around. Technology should make your job easier, not more complicated. Discovery SpaceClaim enables you to create, edit, or repair geometry without worrying about underlying technology. With Discovery SpaceClaim, working with 3D modeling software becomes fast, easy, flexible, and rewarding, no matter where in the workflow you need it. Regardless of a model’s origin, you can open the file in Discovery SpaceClaim and add or subtract geometry in any way you visualize. With streamlined commands and workflows, operations that previously took hours can be completed in minutes. You’ll find learning Discovery SpaceClaim easy — weeks instead of months – and realize a return on your investment that’s faster than expected.

Ways to Access SpaceClaim Technology

The SpaceClaim technology can be accessed as ANSYS Discovery SpaceClaim through the ANSYS Discovery Essentials, Standard, or Ultimate bundles. It is also available as ANSYS SpaceClaim Direct Modeler (SCDM) standalone or through the ANSYS Mechanical Enterprise, ANSYS CFD Enterprise, and multiphysics bundles.

RECENT NEWS

Did you know? IIA’s Irvine, CA Lab has one of the Largest Area Laser Scanner CMMs in the U.S.