GAGE-CHEK 2000

Design

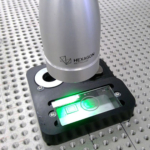

Thanks to its rugged industrial design, the GAGE-CHEK 2000 is superbly suited for applications in measuring rooms as well as in harsh production environments. Its slim aluminum housing with integrated power adapter and fanless passive cooling system is exceptionally sturdy and resilient. The unit’s straightforward touchscreen, made of specially hardened glass, supports multitouch gesture control and permits operation with gloves.

Functions

The logical arrangement of menus and function elements provides intuitive user guidance that supports you in the use of the various functions. Along with the typical functions of an evaluation unit, such as zeroing and preset setting, the GAGE-CHEK 2000 also offers the following useful features:

- Configurability of each axis for length or angle display

- Measurement series with recording of minimum and maximum values

- Simple switching of the counting direction

- Measured-value output—either manually, continuously, or when triggered by a touch probe

- You can transfer the captured measured values to a PC via the data interface

Software options

Software options allow you to adapt the range of functions of the GAGE-CHEK 2000 to your given requirements. You can enable these software options by entering a license key.

Intuitive display

All of the information you need is displayed in a clean and easy-to-read layout on the unit’s high-resolution, 7-inch color flat-panel screen. Only those functions that are actually available within a given context and situation are shown. The self-explanatory operating controls provide intuitive user guidance.

RECENT NEWS

Did you know? IIA’s Irvine, CA Lab has one of the Largest Area Laser Scanner CMMs in the U.S.