Dimensional Inspection

Dimensional Inspection (also known as: metrology services, validation, verification, product evaluation, contract inspection, and layout inspection) is performed to compare the actual condition of a manufactured part or component to the nominal condition as defined by engineering drawings and blueprints, metal or film templates (decreasingly), digital files and 3D CAD models (increasingly), or even a master tool or part.

As there are many ways to establish product definition or to define design, there are even more ways to measure and inspect the actual product manufactured. Being fully cognizant of this, Q-PLUS Labs has amassed and developed an impressive array of state-of-the-art measuring instruments, equipment and technology. These technologies, coupled with our staff of highly skilled, trained, and experienced professionals, sustain a consistently high-quality yet cost-effective service unmatched in the industry. The end result for you is impartial, unbiased, and comprehensive dimensional measurement information you can depend on.

Our expansive environmentally controlled laboratories are amply equipped to handle virtually any inspection need, big or small, with accuracies and measurement resolutions down to mere nanometers. Timely, easy-to-understand results can be provided in a variety of reporting formats including customer-specific formats. Also see our Additional Inspection Specialties page for even more dimensional inspection services offered by Q-PLUS Labs.

Q-PLUS Labs offers a variety of first article inspection services:

- Comprehensive and accurate

- Big or small, simple or complex

- Variety of easy-to-understand first article inspection reports

- Custom formats

It’s critical to have viable and reliable means of accurately verifying your manufactured products and manufacturing processes. One of the primary ways to accomplish this is via an in-depth evaluation of the first piece from your production run — also called first article inspection. Perhaps you have no in-house metrology capability, or that capability is overloaded. You may even want to have your in-house inspection verified. Always, you want to be sure that if you’re going to make it, you make it right! Q-PLUS Labs provides exceptionally comprehensive and accurate First Article Inspections the way you need it, when you need it.

|

|

|

|---|

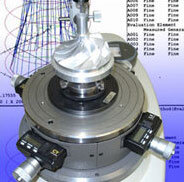

DCC-CMM Full Automation Capability

- Fast, reliable & economical

- Excellent repeatability

- Production parts

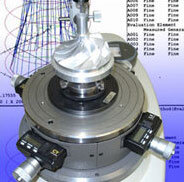

DCC-CMM is the acronym for Direct Computer Control Coordinate Measuring Machine. A DCC-CMM is a programmable fully automatic universal dimensional measurement machine. It is the foundation of modern metrology and the predominant measuring equipment employed. With a growing emphasis on control of the on-going process, DCC-CMM or CNC-CMM (Computer Numerical Controlled Coordinate Measuring Machine) capabilities allow us to quickly and economically inspect large quantities of a given part or configuration. Whether it is a series of production part inspections, statistical samples for analysis, or a set of critical features for the entire lot, we offer the confidence of doing it right the first time, on time.

|

|

|---|

All of our CMMs can be programmed when inspecting more than one part. Part inspection programs can be either “learned” as the first part is inspected or programmed off-line. We can even write vector-driven programs to your 3D CAD solid model. Our robotic DCC-CMM capabilities offer the greatest savings in turnaround and cost as well as high gage repeatability and reproducibility.

Non-Contact Inspection

Non-Contact Inspection

- Optical video probing & measurement

- Laser probing & sensing

- 3D white light scanning

- Laser scanning

- Robotic multi-sensor measurement systems

- Laser size measurement

What if the product or aspects of the product are too small or too soft to use contact inspection techniques? No problem! Our non-contact video and optical inspection methods are the solution. Q-PLUS Labs has several non-contact capabilities ranging from more conventional optical video probes, to laser probing and sensors, 3D white-light scanning, and fully programmable robotic multi-sensor measurement systems. World-class optics are utilized for unsurpassed imaging accuracy with magnifications upwards of 1000X and resolutions down to one-millionth of an inch.

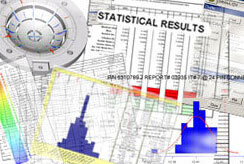

Capability Studies & Statistical Analysis

Capability Studies & Statistical Analysis

- SPC

- Gage R&R

- PPAP

SPC (Statistical Process Control) is the statistical analysis of measurement data collected from a manufacturing process to determine its viability and make educated corrections to a process. SPC is an integral step in the production part approval process. Besides requiring a significant number of repetitive measurements (for which DCC-CMMs are nearly indispensable), complex data compilation, analysis and interpretation are required. Q-PLUS Labs routinely provides statistical results (such as Cpk, Cp, Ppk, Pp, Sigma level, etc.) supported by quantitative measurement data and depicted in a variety of graphical analyses.

Capability Studies provide a greatly enhanced examination and validation of manufacturing processes. These are commonly utilized in high-production applications such as automotive, components and commercial products. Q-PLUS Labs provides many types and degrees of capability studies tailored to any application or special customer requirements.

An important component of any comprehensive capability study is analysis of the measurement process itself. A Gage R&R (Repeatability & Reproducibility) study is a common way to determine what amount of error in a process is due to measurement uncertainty.

PPAP (Production Part Approval Process) is a standard requirement in the automotive industry that occurs at the beginning of or after a change to a manufacturing process.

Contour Analysis 2D & 3D

Contour Analysis 2D & 3D

- Model based definition

- Part-to-CAD comparisons

- Vector-driven key features

- 3D best-fit

- Vane & blade specialists

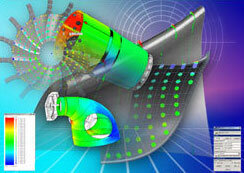

Modern product definition is commonly achieved by geometric dimensioning and tolerancing through a 3D CAD model. This is particularly important where complex, non-prismatic, free-form or organic geometry exists, as conventional dimensioning is not feasible.

Q-PLUS Labs is fully conversant with Model Based Definition. Unusual shaped geometry requires unusual verification techniques. We have a wide array of special equipment, software and techniques to properly analyze 2D and 3D contours. Our methods both qualify and quantify the results.

Q-PLUS Labs provides innumerable application-specific solutions ranging from abbreviated vector-driven key features inspections to extremely comprehensive part-to-CAD comparisons using high-density scan data. Such analyses can be best-fit using a number of algorithms to achieve “by-the-book” results for complex profile requirements.

Surface Finish Analysis

Q-PLUS Labs offers advanced surface finish analysis and surface mapping and metrology capabilities including graphical depictions, numerous sensor configurations, many algorithm and post-processing options, and even the raw surface finish data. All surface finish measurements comply with ASME-B46.1.

How we acquire surface finish data:

- Skidded 2D Contact Profilometry – This type of measurement process involves a gage with a sensitive stylus contained within a probe attached to a metal rest pad or skid that rests on the object being analyzed. The stylus and skid move together to measure the average roughness of the part’s surface.

- Skidless 2D & 3D Contact Profilometry – Skidless surface finish analysis is a contact measurement method of acquiring finish data with a stylus. Because the skidless gages use an internal precision reference surface, these gages can measure form and waviness in addition to roughness on a micro-inch level.

- Noncontact 2D & 3D Optical Profilometry – This profilometry is a non-contact method which accommodates many sample geometries via chromatic confocal technology which uses white light to collect measurement data. However, whereas interferometry uses the superposition of waves after they are reflected off the object, chromatic confocal sensors measure the wavelength as it hits the surface of the object.

- Nano Scanning – Nano Scanning involves 3D scanning at the sub-micron level and is accomplished with a chromatic confocal sensor. This type of scanning can be used to measure or digitize very small geometry and can also acquire surface roughness data.

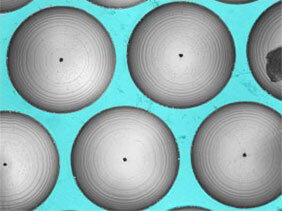

Form and Roundness Testing

Form and Roundness Testing

- Ultra-high accuracy contour tracing

- Ultra-high accuracy roundness, form, and GD&T testing

- Cylindricity testing & measuring

- Internal thread forms

- Knife-edge sharpness

- Involute forms & serrations

- Ball screw Gothic arch forms

While the typical CMM is an extremely versatile instrument, many precision measurements simply cannot be properly made due to size, tight-tolerance requirements and the like. For such situations, Q-PLUS Labs utilizes ultra-high accuracy purpose-specific measurement devices including a contour tracing profile scanner and a form tester that can measure roundness, cylindricity, flatness, run-out, perpendicularity and many other GD&T (Geometric Dimensioning & Tolerancing) requirements.

Both instruments are continuous contact, bridging the best of the analog and digital worlds. These instruments are also fully automated and programmable.

Nano Measurement

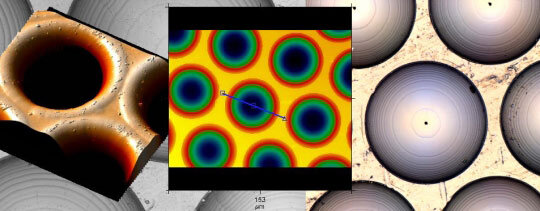

Mainstream metrology has gradually outgrown the limits of the “micro” and is increasingly expanding into the realm of the “nano” for advanced microscopy and analysis. With the advent of nanotechnologies and growing demand for micro-manufacturing, the need for the ability to accurately measure very small objects and geometry has increased the need for measurement beyond the micro, to the nano.

Typically, surface finish has required the highest precision in dimensional metrology. However, the need to characterize surface conditions has steadily moved beyond what conventional surface finish 2D analyzers can measure, which has caused an increasing rise in the need for nano measurement. While specifications for 3D surface finishes have existed for some time, they have rarely been specified in engineering drawings due to the inability to easily obtain such measurements that nano measurement can provide.

|

|

|

|---|

Q-PLUS Labs provides a variety of nano measurement capabilities and inspection services. In addition to surface finish in 2D and 3D, now very small geometry can be dimensionally characterized and inspected. The technology utilized ranges from stylus profilers to confocal laser microscopy to white light interferometric optical profilometry. Relevant characteristics include flatness, wear, texture, sharpness, and other conditions that can affect functionality but might not otherwise show up in a dataset of conventional metrology measurements.

Practical applications include:

- Surface finishes

- Bearings

- Medical blades

- Seals

- Precision valves

- Artificial joints

- Inkjet cartridges

- Extremely small parts

Outputs can range from simple surface finish readings to full 3D analysis. Obtained data can also be provided in formats ranging from a point cloud to fully parametric 3D CAD models.

Additional Inspection Specialties

At Q-PLUS Labs, we offer a wide range of dimensional inspection and measurement services, including:

- Ultra-High Accuracy Measurement

- Validation

- Measurement Studies

- Potting and Sectioning

- Blue, Scribe and Layout

- Part Sorting and Separation

- Failure Analysis

- Force Testing

- Dispute Resolution

RECENT NEWS

Did you know? IIA’s Irvine, CA Lab has one of the Largest Area Laser Scanner CMMs in the U.S.