Home >Company >Employment Opportunities>Sr. Coordinate Measurement Machine (CMM) Programmer – FT (All Shifts)

Sr. Coordinate Measurement Machine (CMM) Programmer – FT (All Shifts)

Established in 1987, Q-PLUS Labs is a leading precision dimensional measurement laboratory providing a one-stop, fully comprehensive solution to a wide array of quality services, inclusive of precision measurement, inspection, reverse engineering, 3D scanning, CT scanning, modeling, FAI, part sorting and other quality-related needs. Our facility is one of the most well-equipped and uniquely capable independent precision dimensional measurement laboratories in the world. Along with being an ITAR registered lab, we are also ISO 9001 registered, AS9100 certified, ISO 13485 certified and ISO 17025 accredited, as well as being a long-time member of the American Society for Quality (ASQ), with all measurements traceable to National Institute of Standards and Technology (NIST). Our customers are leaders in the high technology, medical, defense, automotive, and aerospace sectors, among other industries.

Due to our increasing volume of work, we are currently seeking an experienced and knowledgeable Sr. CMM Programmer for a full-time position, working in a demanding, high-technology, fast-paced environment, where accuracy and quality are the highest priority.

Position Summary

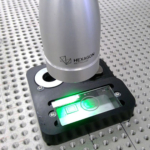

This position will require the use of Zeiss Calypso, PC-DMIS, MCOSMOS, as well as other CMM software in the programming and operation of a large variety of CNC-CMMs and other high-end metrology equipment; thus, the successful candidate must have extensive knowledge and background in these programming languages. Additionally, a complete understanding of the reading of blueprints and Geometric Dimensioning and Tolerancing (GD&T) is also required, along with the usage of various measurement hand tools and gauges.

Job Functions

- Perform extensive dimensional inspections in full capability dimensional inspection/metrology lab.

- Support ISO 9001, ISO 17025, ISO 13485, and ASME Y14.5 policy manuals and requisite procedures

- Ensure accurate blueprint reading and interpretation for a variety of components utilized in various type of manufacturing environments over a wide range of industries (i.e. aerospace, medical, plastics, castings, etc.)

- Develop and implement CNC-CMM programs both online and offline on systems with a variety of contact and non-contact sensors

- Perform, coordinate and assist other Inspection personnel on dimensional measurement & inspection using CNC-CMMs and a variety of other metrology equipment and hand-tools

- Train Quality Technicians on the use of various measurement instruments, the correct review and analysis of blueprints/drawings, and GD&T basics

- Perform dimensional inspection to drawings, procedures & customer specifications

- Generate and methodically review professional reports of measurement results

Qualifications

- Minimum of 5 years’ experience as a Quality Inspector/Technician

- Extensive knowledge and experience in various CMM software such as Zeiss Calypso (preferred), as well as additional programs (PC-DMIS, MCOSMOS, QC-5000, GeoMeasure 6000 and GeoPak 2100)

- Minimum of 5 years’ experience operating a Coordinate Measuring Machine (CMM)

- Minimum of 5 years programming and operating a CNC-CMM

- Extensive knowledge of GD&T per ASME Y14.5

- Possess the ability to program using 2D drawings and 3D CAD models on various machines, both online and offline

- Basic understanding in the performance of measurement uncertainty

- Experience with Vision Systems and 3D Scanners preferable, but not essential

- Knowledgeable in dimensional measurement & inspection using a variety of precision instruments

- Fairly knowledgeable in the use of Microsoft Excel, specifically in its use to process program data into reports

- Excellent verbal and written communication skills, coupled with a strong sense of accountability and integrity

- Excellent concentration and attention to detail with outstanding work efficiency and accuracy

- A self-starter, who is both resourceful and a creative problem solver

Compensation commensurate with qualifications, ability, and relevant experience; benefits include medical, dental, 401k, and pension plan.

Please email jobs@qpluslabs.com to request an application.

(When emailing a resume, please attach the file in a Word or PDF format)

RECENT NEWS

Did you know? IIA’s Irvine, CA Lab has one of the Largest Area Laser Scanner CMMs in the U.S.